As information technology, the essence of the Internet of Things is information and computing. The perception layer is responsible for information acquisition, the network layer is responsible for information transmission, and the application layer is responsible for information processing and calculation. The Internet of Things connects a large number of goods data, which are new data that have not been processed before. New data combined with new processing methods create a large number of new products, new business models, and comprehensive efficiency improvement, which is the fundamental value brought by the Internet of Things.

Industrial Internet of Things (iot) is still an important part of information development. Chinese policies have been published successively to explore the industrial chain ecological construction of iot. Popular industrial iot is intelligent industry, will have a perception, monitoring capability of acquisition, control, sensor and mobile communications, intelligent analysis technology continuously into the industrial production process each link, so as to greatly improve manufacturing efficiency, improve product quality, reduce product cost and resource consumption, eventually replace the traditional industry.

The Industrial Internet of Things (iot) is a platform for diversified integration and mutual exploration between different elements, which can connect various sensors, controllers, CNC machine tools and other production equipment in the production site. Create a wider range of platforms in different fields, industrial data acquisition platform, Furion-DA platform, etc. With the development of the Industrial Internet of Things, the intelligent devices connected to the industrial Internet of Things will be increasingly diversified, and the massive data generated by the network interconnection can be transported to any place in the world.

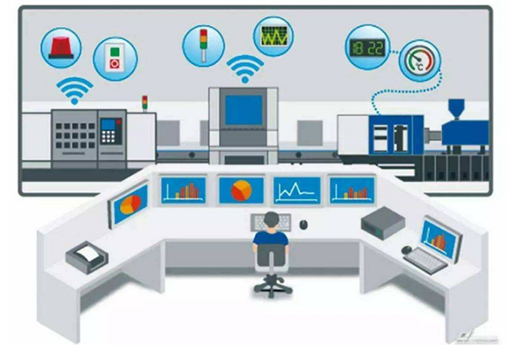

By perception technology, communication technology, transmission technology, data processing technology, control technology, applied to production, ingredients, storage, etc all stages of production and control of digital, intelligent, networked, improve manufacturing efficiency, improve product quality, reduce product cost and resource consumption, finally realizes the traditional industry to a new stage of intelligent. At the same time, through the cloud service platform, for industrial customers, the integration of cloud computing and big data capabilities, to help the transformation of traditional industrial enterprises. With the increase of data volume, edge computing, which tends to process data at the data source, does not need to transfer data to the cloud, and is more suitable for real-time and intelligent data processing. Therefore, it is safer, faster and easier to manage, and will be used more effectively in the foreseeable future.

The Internet of Things emphasizes the connection of all hardware devices in life and production; Iiot refers to the connection of production equipment and products in an industrial environment. Iiot turns every link and device in the production process into a data terminal, collecting the underlying basic data in an all-round way, and conducting deeper data analysis and mining, so as to improve efficiency and optimize operation.

Unlike the use of iot in consumer industries, the foundations for iot in the industrial sector have been in place for decades. Systems such as process control and automation systems, industrial Ethernet connections, and wireless Lans have been operating in factories for years and are connected to programmable logic controllers, wireless sensors, and RFID tags. But in the traditional industrial automation environment, everything just happens in the factory's own system, never connected to the outside world.

Post time: Sep-08-2022